Aspiration Energy Collaborates with IIT Madras for Certificate Program in Industrial Heating

Aspiration energy in association with IIT Madras conducted a 2-day Certificate Program in Industrial Heating on 23rd and 24th September. The event was held in the IC & SR building within the IIT Madras Campus.

The main speakers of the event included Dr. Satyanarayanan Seshadri (Assistant Professor at IIT Madras), Mr. Bhoovarahan Thirumalai (CEO of Aspiration Energy) and Mr. Muthuvel (Senior Engineer at Aspiration Energy). The topics covered ranged from design and sizing of solar thermal systems & heat pumps, to their cost economics and O&M requirements. To make things interesting, a live demonstration of a working heat pump was also conducted on the second day.

The event saw active participation from energy professionals and engineers from various industries, energy consultants, renewable energy enthusiasts as well as newbies interested in exploring innovative technologies.

Figure 1: Interactive session between the Professor and attendees in the conference room

Now, let us discuss the technology and highlights of the event in detail.

Industrial Heating

Now, when it comes to solar heating, the natural direction of thought by most people is its application for domestic heating purposes, which are essentially the solar heaters used in many homes. In fact, this is where most of the solar thermal heating installations have been in the past five decades.

As far are industries are concerned, heat as an energy source has not historically been given sufficient emphasis. Being considered a lower form of energy in comparison to electricity, heating is often disregarded when an energy engineer has to suggest plant to improve the overall plant energy efficiency.

In many industrial applications, heating can contribute 30-40% of total energy requirements. A surprising statistic is that about 20% of all energy requirements in India is industrial heating below 250 degrees Celsius.

Two innovative technologies for industrial heating applications have been discussed in this event.

- Evacuated tube collectors

- Heat pumps

Evacuated tube collectors

Evacuated tube collectors (ETC) utilize the heat from the sun and make its available for water heating purposes. Typically, the applications include domestic water heating as well as industrial water heating purposes.

Aspiration Energy developed an innovative ETC technology for industrial heating solutions up to 120 degrees Celsius.

What is interesting about this technology is that it can maintain a temperature of 90-95 degree Celsius for heating requirements in industrial processes for a period of up to 24 hours. The is despite the fact that the optimal heating hours being just 6!

Take a look at one of their installations.

Figure 2: One of Aspiration Energy’s thermal collector installations

Notice the tilt of the device. This aids in optimal heating of water.

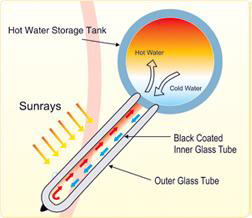

As depicted in the graphic below, the cold water enters the tube and flows down, aided by gravity. As heat transfers from the sun, the water gets heated. This hot water rises and exits to the buffer tank, which is in turn used for industrial process applications.

Figure 3: Working principle of ETC systems

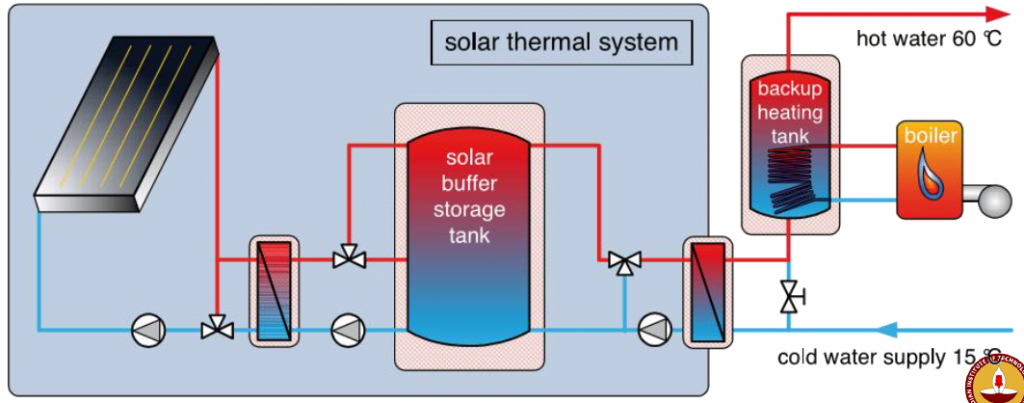

The typical arrangement of an ETC solar thermal system comprises:

- Collectors

- Heat exchangers

- Storage/buffer tanks

- Pumps & controllers

The schematic for an industrial heating system is given below.

Figure 4: Schematic of a solar thermal system for industrial heating

With Aspiration Energy’s innovative system design, minimum guaranteed temperature of up to 75 ̊ C can be provided without any fluctuation in the output.

It is expected to have a lifetime of 20 years with the O&M cost amounting to just 1.5-2% of total cost.

Heat Pumps

Heat pump is an energy efficiency device that utilizes a small amount of energy (electricity) to transfer heat from one location to another.

Unlike solar thermal collectors, heat pump is a passive solar heating device. Rather than direct solar radiation like solar thermal collectors, heat pumps utilize the atmospheric heat energy (or ground heat) to heat a space. In order to transfer heat from a heat source at higher temperature to a heat sink at a lower temperature, some work has to be done. This work (energy) is input in the form of electricity.

A heat pump is considered to be 300-400% efficient. Okay, this does not mean it defies thermodynamics! It only means that the only input is electricity and the heat is extracted from the ambient air.

A live demonstration of heat pumps was conducted in one of the IIT labs. Take a look at some pictures.

Figure 5: Demonstration of heat pump

Figure 6: Heat pump unit with heat exchanger, compressor and expansion value

Figure 7: Buffer tank

Comparison of the two technologies with solar PV

Now, there is a lot of buzz among industry professionals on which of the two solar technologies (solar PV or Solar thermal) is better. Of course, the cost economics has not favored solar thermal for electricity generation. But is it so for heating?

The final session of the event covered this part.

The table below provides you with broad understandings on the three technologies: solar PV, solar thermal (ETC collectors) and heat pumps.

| Parameters | Technology | ||

| Solar PV | Solar Thermal Collectors (AEPL solution) | Heat Pumps | |

| Purpose | Electricity | Heat | Heat (with input electricity) |

| Efficiency | 16% | 60-70% | 300-400% |

| Area per kW (sq. m.) | 10 | 3 | Very minimal |

| Cost (Cr/MW) | 6 | 3 | 4 |

| Generation (lakh/MW per year) | 15 | 15 | Depends on no. of hours used

· 15 (6 hours) · 30 (12 hours) · 45 (18 hours) |

| Payback (years) | 5-6 | 1-3 | <1 |

Some insights with the above table as the reference are provided below.

- Assuming you have similar electricity and heat requirements for your factory, the cost economics favor solar thermal (for heating) rather than solar PV (for electricity generation). But, if your heating requirements are low or nil, there no point in even considering heat pumps or solar thermal.

- Note that efficiency is not measure of the superiority of the technology. A higher efficiency only means that it requires lesser area for the same plant capacity. For example, in an area of 3000 sq. m., a solar PV plant of 300 kW can be installed. This is in contrast to the solar thermal collectors for which a 1000 kW capacity can be put up in the same area. So, that is three times the capacity for the same area. Therefore, for the same area, the generation is higher for the solar thermal heating system. What this translates to for an industrial end-user is that, if the heating requirements are significant, then it is better to go for a solar thermal system than solar PV.

- For heating purposes, the table shows that heat pumps provide a better payback for your returns than solar thermal collectors. But it is just not that simple! What is not considered here is the final cost of energy. It is important to note that heat pumps also use some input electricity, which is an extra expense. And statistically, electricity tariffs have only increased. When this electricity requirement is taken into consideration, the numbers simply may not favor industries that plan to use heat pumps for a longer period . Therefore, when you consider the final cost of energy for, say, a 10-year period, solar thermal can turn out to be lucrative.

- Another metric to be considered is rooftop space available. Heat pumps are considered a better option than solar ETC collectors if the space available is less, which is the case in many hotels and commercial establishments.

- A disadvantage associated with ETC collectors is that, being a new and emerging technology, it requires personnel with specific skillsets to perform the maintenance. On the contrary, heat pumps can be operated upon by any air-conditioner technician due to which they are considered to be very reliable.

In conclusion, it can be said that the selection of the right technology for your requirements depends on a couple of critical factors, which include

- Rooftop space available

- Energy utilization

- Payback period

- Final cost of energy

The event ended with distribution of certificates for all the participants.

Figure 8: Mr. Bhoovarahan distributing (centre) certificates to the participants

Figure 9: The whole team at the workshop

Solar Mango feels that the event turned out to be successful, both in terms of educating the industry about new and innovative technologies as well as creating a platform for interaction with different stakeholders in the industrial and technology domains.

Good luck to Aspiration Energy for organizing more such workshops!!